Content

Why Fast CRM for Inventory is Crucial for Business

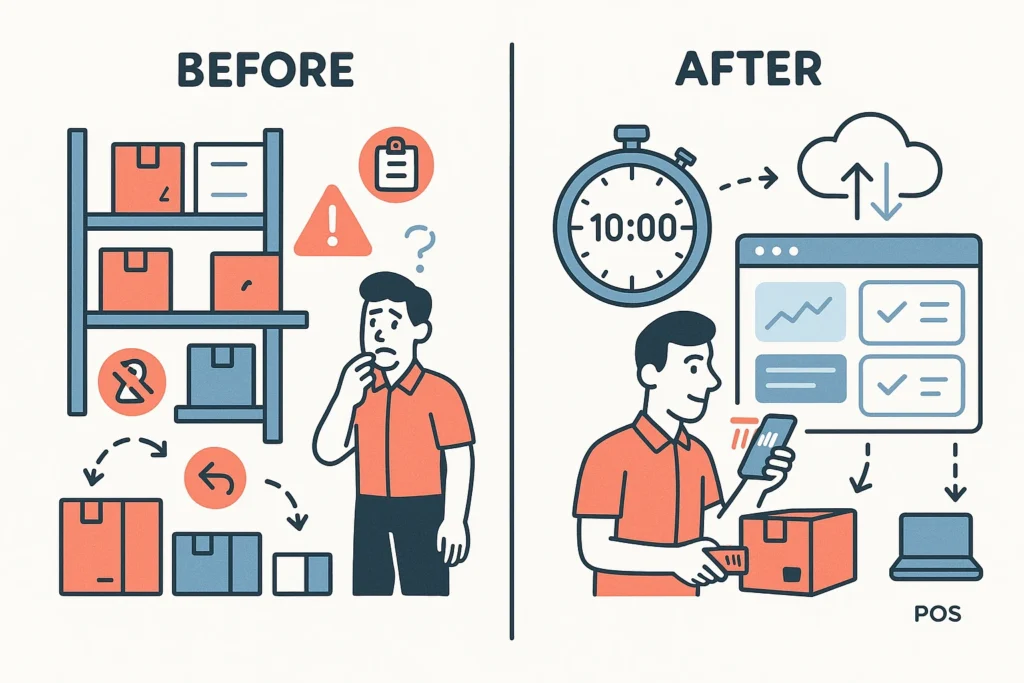

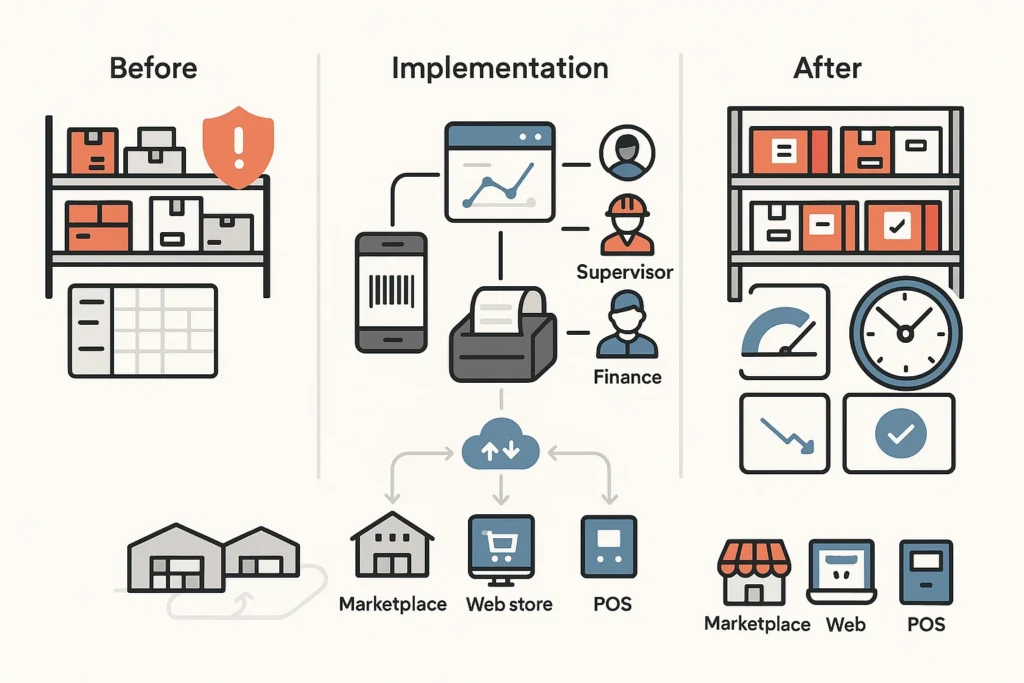

Modern retail and e-commerce operate in a state of constant change: demand fluctuates daily, product ranges expand, and sales channels multiply. In such an environment, inaccurate stock levels lead to a chain of problems – from pricing errors to supply chain disruptions and marketplace blocks. Inventory management transforms from a routine operation into a strategic process that directly impacts profit and turnover. However, traditional approaches often require halting sales, night shifts, and involving a large number of staff.

Practice shows that businesses need a different model – short, regular, technology-supported sessions that are carried out without stopping sales and ensure high accuracy. This is how the concept of 10-minute inventory works, where accounting is performed in compact warehouse areas or for selected priority SKUs with instant validation in the system. In this article, we will explain how to set up the process to be fast, controlled, and transparent, and we will show the benefits of using HugeProfit CRM as an operational platform for daily accuracy.

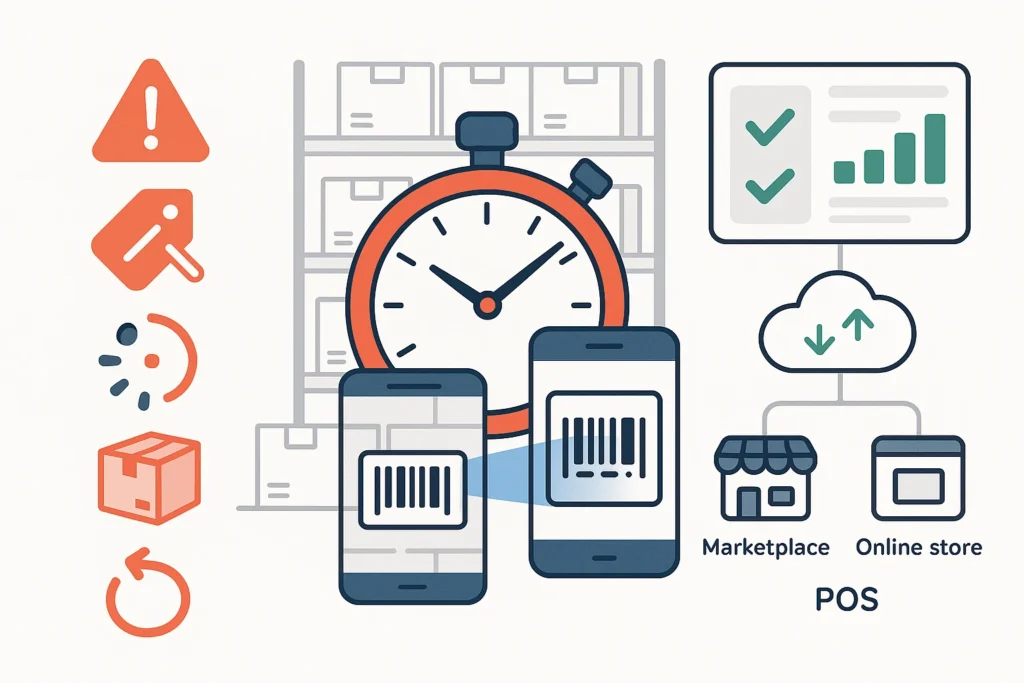

In CRM for Inventory, scanning and reconciliation tools allow you to perform inventory in 10 minutes during working hours without stopping sales.

Typical Losses from Inaccurate Stock and How to Avoid Them

The most noticeable losses occur when actual stock levels diverge from recorded ones. Incorrect supplier orders are placed, funds are frozen in excess stock, and deficit items are not replenished. This causes order fulfillment failures, marketplace penalties, rating drops, and lost sales. Add to this costing errors – if batches and returns are accounted for incorrectly, the margin at the SKU level is distorted, and management decisions become risky.

Another scenario is price and stock mismatches between channels, where different data is displayed on the website, offline store, and marketplace. As a result, customer experience is ruined, the number of cancellations and returns increases, and support workload grows.

Preventing these losses starts with discipline and technology. First, a unified nomenclature with structured fields, barcodes, and clear rules for creating new items is required. Second, mandatory scanning during receipt, movement, and shipment drastically reduces the risk of human error.

Third, daily or weekly short checks of specific warehouse zones help detect discrepancies at an early stage when they are easy to fix. In CRM for Inventory, these approaches are implemented through quick inventories with mobile scanning, recording the reasons for discrepancies, an action log, and access rights. After reconciliation, the system automatically updates stock levels and, if necessary, recalculates costs considering batches and markdowns – closing the margin control loop.

What Does 10-Minute Inventory Mean in Practice?

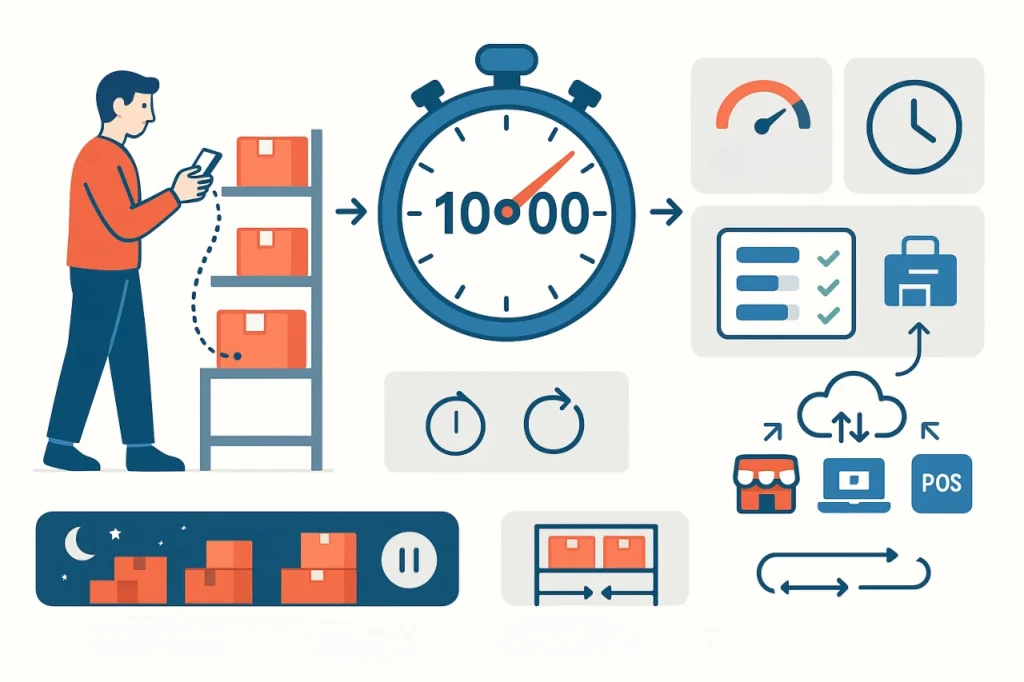

10-minute inventory is not an attempt to count the entire warehouse in minutes. It refers to a short-duration cycle count that focuses on a specific area or selection of goods. For example, one shelf, bin, top ABC items, or a group of high-turnover SKUs is checked daily. The session is launched in the CRM, a warehouse and zone are selected, and the employee sequentially scans the labels.

The system instantly compares the scanned quantity with the expected one, highlights discrepancies, offers correction options, and requires specifying the reason – misplacement, incorrect storage, defects, write-offs, or returns. The key advantage of this format is that it is performed during working hours without stopping shipments and cash operations, and the results are immediately reflected in reports.

In HugeProfit, no specialized equipment is required for such sessions – a smartphone with a camera or a data collection terminal is sufficient. Offline mode with subsequent synchronization, printing labels with QR or barcodes, and working with weighed goods are supported. Through templates and roles, the process is formalized: who can initiate inventory, who approves changes, and who analyzes discrepancies. This control reduces the warehouse manager’s workload and creates a culture of constant accuracy – small daily steps keep the system in order, which is much more effective than rare and painful full recounts.

The Role of CRM in Accelerating Accounting Processes

Without a centralized system, even good regulations fall apart – data is fragmented across spreadsheets, chats, and different programs, history and accountability are lost. Inventory CRM brings order to directories, workflows, and roles, ensuring a single source of truth for stock and prices. In HugeProfit, this is supported by practical tools: mobile scanning, an operation log, role-based access, convenient distribution across warehouses and virtual warehouses, order reservations, as well as integrations with marketplaces and online stores. After each short session, the system automatically publishes up-to-date stock levels to all connected channels – the risk of double sales disappears, and procurement planning is based on real data.

Equally important is that CRM accelerates management analytics. When inventories are performed regularly, it is easy to measure accuracy rate, track shrinkage, identify problem areas, and the causes of discrepancies. Based on this, the manager builds an improvement plan – relocating bins, changing picking routes, correcting packaging, and training staff. The recalculation of cost and margin after reconciling discrepancies happens automatically, eliminating the risks of manual formulas and ensuring correct reporting by SKU, category, and channel. As a result, the business gets not just fast inventory, but a managed accuracy cycle that works daily and directly impacts profitability.

This introduction sets the framework for the entire material: next, we will formulate clear criteria for 10-minute inventory, prepare technical requirements, describe a step-by-step algorithm in HugeProfit, analyze work with batches and multi-warehouse, consider typical mistakes, and post-inventory analytics. The goal is simple – to provide you with a practical scenario that can be implemented this week and maintained without stopping sales.

The Concept of 10-Minute Inventory: Criteria and Expected Results

Fast inventory is a regular, short-duration cycle count that checks a selection of goods or a specific warehouse area without stopping sales. The goal is to maintain high stock accuracy on a daily basis and instantly eliminate discrepancies. In CRM for Inventory, the session starts with selecting a warehouse, zone, and list of SKUs, followed by scanning, automatic reconciliation, and recording the reasons for deviations with access rights and an action log.

KPI of Fast Inventory: Accuracy, Completeness, Time

For 10 minutes to bring measurable results, clear metrics are needed:

- Accuracy (accuracy rate) – the percentage of items without discrepancies. The target is 98% or higher for the checked sample.

- Completeness – 100% of items in the specified zone or SKU list must be scanned.

- Time per session – no more than 10 minutes from start to result approval.

- Productivity – number of scans per minute and percentage of exceptions requiring reconciliation.

- Stability – frequency of execution according to the schedule (daily or by ABC calendar).

- For fast warehouse inventory, it is critical that CRM for Inventory is maintained using a unified nomenclature and barcodes.

HugeProfit provides instant validation during scanning, highlights discrepancies, requires a reason for correction, and saves photos and comments. This turns KPIs into manageable indicators, not one-time figures.

Scope of Application and When Extended Audit Is Needed

The 10-minute format is effective if there is basic discipline: barcodes or QR codes, unified nomenclature, and shelf labeling. If the accounting is unbalanced, codes are missing, and there are many unnamed items, it is worth starting with a preparatory stage: normalizing directories, printing labels, and setting up roles. Extended audit is advisable for jewelry, serial numbers, high-value goods, or when large discrepancies are found in groups. A full recount is also needed for inventory on a specific date for external checks. When CRM for Inventory is set up correctly, short sessions provide accurate results in 10 minutes, even in a multi-warehouse environment.

In HugeProfit, the scope is managed by regulations: who starts the session, who approves changes, and which reasons are allowed for corrections. There is an offline mode and synchronization, support for batches and expiration dates, which is critical for FMCG and pharmaceutical formats. This allows combining short cycles with planned in-depth checks.

Comparison with Traditional Inventory Approaches

Traditional inventory is usually rare and labor-intensive – stopping operations, night shifts, and significant staff involvement. It provides a snapshot on one date but does not maintain daily accuracy. Fast inventory works as a continuous process – small areas are checked frequently, errors are caught early, and the impact on sales is minimal. The risk of systemic deviations is lower because data is constantly balanced. This approach ensures online warehouse accounting with up-to-date stock levels in all channels without stopping operations.

HugeProfit Inventory CRM enhances the advantages of the cyclical approach: a session planner based on ABC and XYZ logic, checklists for zones, automatic publication of current stock levels to channels, a history of reconciliations, and cost recalculation when quantities change. As a result, the business gets not a one-time campaign, but a managed accuracy cycle – with transparent roles, SLAs for execution, and exception analytics. Ultimately, 10-minute inventory becomes a repeatable process with measurable KPIs and clear accountability. This is the expected result of the 10-minute format: consistently accurate stock, fewer penalties and cancellations, faster procurement planning, and margin control at the SKU level.

Mobile applications of the CRM system HugeProfit

Use all the advantages of a mobile device for inventory management:

– mobile barcode scanner

– adding sales in 2 clicks

– creating and tracking TTN

– controlling balances on Prom, Rozetka, OpenCart, Woocommerce, Khoroshop

– Many warehouses and employees

Preparation for Fast Inventory

Unified Nomenclature and Barcodes

The foundation of accuracy is a unified product card with SKU, units of measurement, and barcode. HugeProfit Inventory CRM ensures centralized directory management and field validation when creating items. For batch accounting, add series, expiration dates, and rounding rules. When inventory in CRM is built on a unified nomenclature, 10-minute inventory proceeds without interruptions.

Shelf Labeling and Scanning Route

Mark rows, shelves, and bins, and print labels with QR codes. In HugeProfit, a route is formed for each zone so that fast warehouse inventory moves sequentially and without omissions. The rule is simple: one shelf – one short session. This allows online warehouse accounting during working hours without stopping shipments.

Roles, Access Rights, and Event Log

To avoid mistakes, separate roles: the operator scans, the foreman approves discrepancies, and the accountant controls cost. Inventory CRM records the reasons for deviations, photos, and comments, and the event log preserves accountability. This discipline makes 10-minute inventory repeatable and manageable.

Equipment Checklist and Minimum Requirements

To start, a smartphone with a camera or a data collection terminal, a mobile label printer, and stable Wi-Fi are sufficient. HugeProfit has an offline mode with subsequent synchronization, which is critical for large warehouses. Prepare a stock of labels, charge the devices, and perform a test scan. When the infrastructure is ready, fast warehouse inventory becomes a daily operation, and inventory in CRM remains up-to-date in all channels.

Technical Requirements for Inventory CRM

Mobile Scanning and Working with Smartphones

Inventory CRM must work correctly with a smartphone camera and data collection terminal: fast autofocus, batch scanning, and operator prompts. HugeProfit supports EAN/UPC barcodes, QR codes, and GS1, serial numbers, and weighed goods. Instant quantity validation, duplicate warnings, and storage location hints reduce errors, so 10-minute inventory is performed without stopping processes. When inventory in CRM is built on a unified nomenclature, fast warehouse inventory becomes a daily routine operation.

Offline Mode and Synchronization

The warehouse operates in areas with weak Wi-Fi coverage, so an offline mode with event buffering is required. In HugeProfit, all scans, edits, and comments are stored locally and sent to the server after connection is restored. Conflicts are resolved according to role priorities and the time of record change. The system shows synchronization statuses so that the operator sees that the data is already on the server, and online warehouse accounting remains consistent across all channels.

Integration with Label Printers and Weighing Equipment

For correct identification, printing labels with dynamic fields is required: SKU, batch, expiration date, and location. HugeProfit integrates with popular label printers, supports templates, and prints directly from a smartphone. For weighed goods, the system generates or reads barcodes with weight so that stock and cost calculations are accurate. This is critical if fast warehouse inventory includes fresh products or cosmetics.

Data Security and Record Version Control

Role-based access management, two-factor authentication, and an event log are mandatory. In HugeProfit, every action is recorded with the user, time, reason, and photo. There is record versioning and the ability to roll back erroneous corrections according to regulations. Backup, encrypted transmission, and API key restrictions ensure that inventory in CRM complies with security policies, and 10-minute inventory does not create data risks. As a result, Inventory CRM becomes a reliable operational platform that supports online warehouse accounting and quickly publishes current stock levels to all connected channels.

10-Minute Inventory Algorithm in HugeProfit

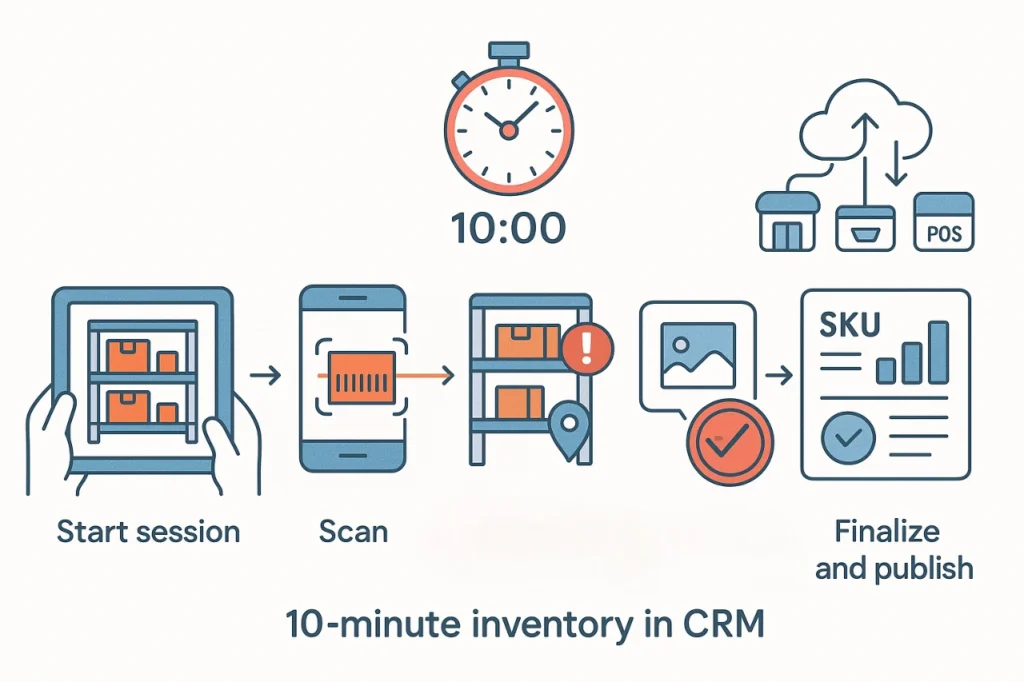

Step 1: Starting the Session and Selecting the Zone

In the inventory module, select a warehouse, specific shelf, or list of SKUs by ABC. The session template defines roles, deadlines, and reconciliation rules. CRM for Inventory immediately shows expected stock levels and suggests a route so that fast warehouse inventory proceeds without omissions.

Step 2: Scanning and Instant Validation

The operator scans barcodes with a smartphone camera or data collection terminal. The system compares the actual quantity with the recorded one, warns about duplicates, incorrect locations, and expired batches. If an item is not found in the directory, it is suggested to add it via a template so that CRM for Inventory remains intact.

Step 3: Automatic Reconciliation and Highlighting Discrepancies

Discrepancies are highlighted in color with a criticality scale. For weighed goods, control tolerance is applied; for serial numbers, uniqueness is checked. In case of an incident, the system suggests the nearest storage locations and last movements, reducing search time and making 10-minute inventory predictable.

Step 4: Reasons, Photos, and Reconciliation

For each correction, a reason and comment are mandatory: misplacement, write-off, placement, or return. Photos of the shelf or label are added. The foreman approves or rejects changes with one click, and the log records the responsible person and time. In this model, Inventory CRM creates a transparent history and simplifies audits.

Step 5: Approval and Cost Recalculation

After completing the session, stock levels are changed, cost is recalculated by batch, and the margin at the SKU level is updated. Data is automatically published to sales channels, ensuring online warehouse accounting without manual duplication. The report shows accuracy rate, shrinkage, and exceptions by reason.

SLA and Execution Schedule

For 10-minute inventory to work stably, set up a schedule: daily mini-sessions for fast-moving groups, weekly for medium, and monthly for slow-moving. KPIs: 98%+ accuracy in the sample, meeting deadlines, a maximum of 2% exceptions requiring recheck. This cycle keeps inventory in CRM constantly up-to-date and minimizes the risk of deviations.

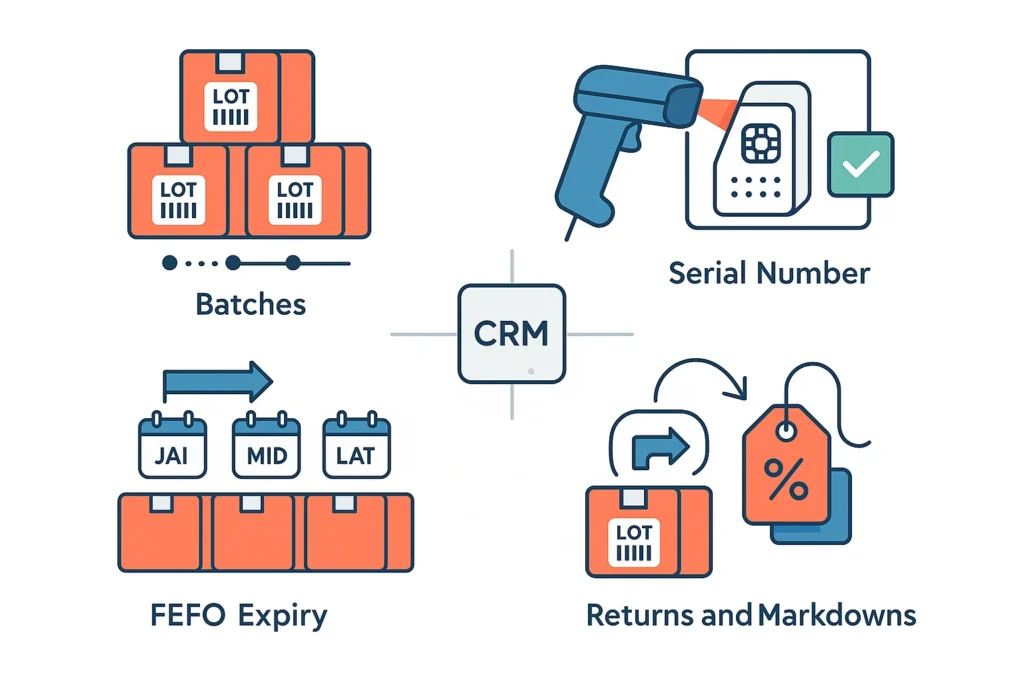

Batches, Series, and Expiration Dates

Batch Accounting and Impact on Cost

For accurate financial results, it is important to maintain batch accounting with the fixation of receipt date, price, discounts, and logistics costs. HugeProfit Inventory CRM automatically links movements to batches and recalculates cost during corrections. When inventory in CRM is built by batches, 10-minute inventory allows quickly detecting misplacement, quantity deviations, and location errors without stopping sales.

Serial Numbers and Full Traceability

Goods with unique serial numbers require increased control. In HugeProfit, serial numbers are scanned and validated during receipt, movement, and shipment, and during fast warehouse inventory, the system immediately shows where a unit is located and who moved it. This simplifies incident investigations, reduces losses, and makes online warehouse accounting reliable for audits and service requests.

FEFO and Expiration Date Control

For categories with limited shelf life, FEFO is applied – picking primarily by the earliest expiration date. Inventory CRM warns about batches approaching the deadline, highlights risky locations, and suggests actions: markdown, rotation, or write-off. During 10-minute inventory, the operator scans the batch label, and the system instantly checks the date and suggests a course of action to prevent margin losses and penalties from sales channels.

Returns, Markdowns, and Margin Correction

Customer returns and markdowns must be recorded in the same batch as the original shipment. In HugeProfit, each correction records the reason, photo, and user, and recalculation is performed automatically according to regulations. This keeps data consistent across channels, and inventory in CRM reflects the actual cost and margin at the SKU level. Regular short checks maintain transparency and make 10-minute inventory an effective tool for financial discipline.

Practical Effect for Operations

Combining batches, series, and FEFO in one platform eliminates the need for complex spreadsheets and manual reconciliations. HugeProfit Inventory CRM integrates scanning, picking rules, and analytics, so fast warehouse inventory becomes a managed process with a predictable outcome. The result is simple – up-to-date stock, minimal write-offs, and stable margin due to online warehouse accounting in a single system.

Multi-Warehouse and Marketplace Integration

Virtual Warehouses and Order Reservations

In a retail network, one product can be sold simultaneously from multiple locations and channels. In HugeProfit, physical warehouses are supplemented with virtual ones – for marketplaces, online stores, click & collect, or pre-orders. This allows distributing stock without double counting and managing shipment priorities. Reservations are created automatically for specific orders and channels, preventing overselling and penalties.

When inventory in CRM is built on this model, 10-minute inventory is instantly reflected in available stock, and online warehouse accounting remains consistent across all sales points. HugeProfit Inventory CRM keeps a complete history of reservations, transfers, and partial shipments, so the manager sees the real picture of demand and availability.

Synchronization of Stock and Prices with Prom, Rozetka, Khoroshop, Shop-Express

Integrations form a single source of truth about the product. HugeProfit synchronizes SKUs, variants, price groups, and publishes available stock to marketplaces and store platforms. After fast warehouse inventory, corrected quantities are automatically updated in the channels, including virtual warehouses and reservations.

Different price lists for B2C and B2B, currencies, and rounding rules are supported. If a product is out of stock, the system hides its offers or switches them to a waiting status. This logic eliminates the gap between warehouse facts and showcase offers, and inventory in CRM becomes the single data source for the entire ecosystem. For categories with batches and expiration dates, correct attributes are transmitted, reducing the risk of erroneous sales.

Warehouse and Sales Channel Prioritization Rules

For stable order fulfillment, clear prioritization is important. In HugeProfit, warehouse selection rules are set: the closest location to the customer, the lowest cost, the highest turnover, or a special channel. For marketplaces, a separate virtual pool can be allocated, and shipments from it can be limited, maintaining a buffer for the company’s own website.

When Inventory CRM manages these rules, the system automatically suggests the optimal picking point and prompts transfers between warehouses. In this configuration, 10-minute inventory not only balances stock but also feeds replenishment planning and product rotation algorithms. As a result, the network gets managed inventory distribution, minimal cancellations, and stable margin due to a transparent model where inventory in CRM and online warehouse accounting work as a single data loop.

Error Prevention and Quality Control

Top Mistakes During Fast Inventory and How to Avoid Them

The most common failures occur due to unclear nomenclature, lack of location labeling, scanning from the wrong shelf, manual corrections without reasons, and untimely synchronization. HugeProfit Inventory CRM eliminates these risks with access rules, mandatory reasons for corrections, photo documentation, and storage location prompts. Implement simple standards: one shelf – one short session, no corrections without scanning, new SKUs are created only via templates. When inventory in CRM is maintained according to a unified scheme, 10-minute inventory provides consistently accurate results and does not slow down shipments.

Control Samples and Rescans

Quality of verification is confirmed by control samples. Allocate a small percentage of zones daily for rescanning by another employee or foreman. In HugeProfit, this is set up via a schedule and checklists; the system shows the difference between the primary and secondary results. This approach allows quickly identifying training gaps and process errors. If the difference exceeds the threshold, an extended check or route correction is launched. Thanks to this, fast warehouse inventory becomes a managed cycle, and online warehouse accounting remains consistent across all channels.

Audit Report and Accuracy Metrics

After each session, generate a transparent report: accuracy rate, number of exceptions, shrinkage, reconciliation time, and percentage of rescans. HugeProfit automatically records the user, reason, photo, and chain of actions, so analytics do not require manual tables. The report in HugeProfit shows discrepancies by reason and zone, highlights SKUs with frequent incidents, and demonstrates how corrections affected the margin. This forms the basis for decisions on training, stock rotation, and procurement. When these metrics are integrated into inventory in CRM, 10-minute inventory becomes a regular process audit, and deviations are closed according to regulations within the established SLA.

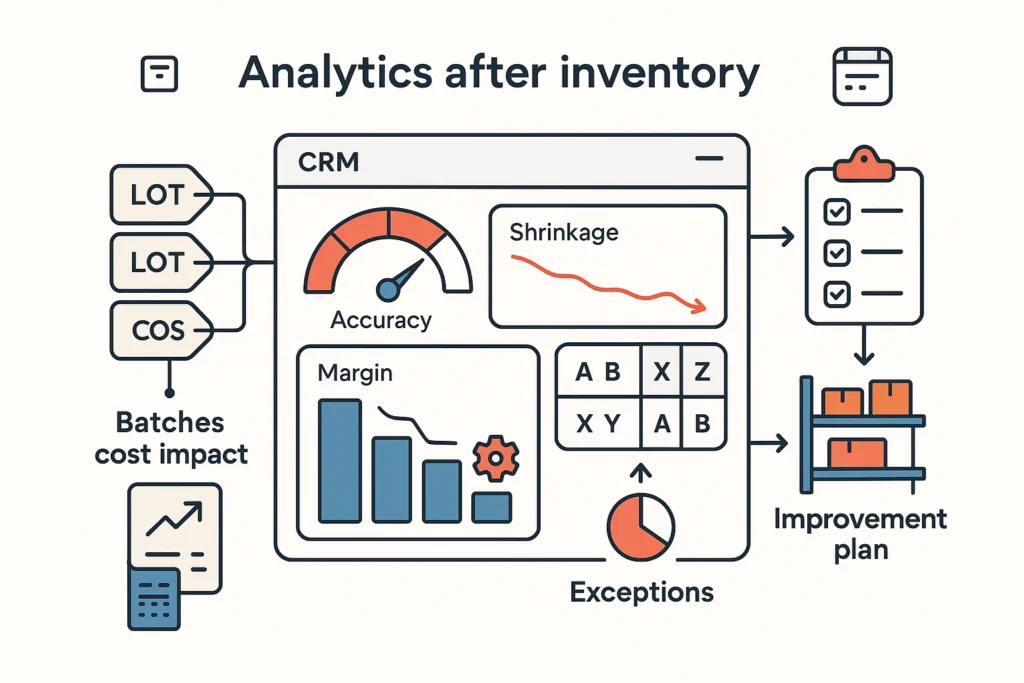

Post-Inventory Analytics

Recalculation of Cost, Margin, and Financial Statement Correction

After the session, the system immediately updates quantities and recalculates cost by batch and FIFO/FEFO rules. If misplacement or write-offs are recorded, HugeProfit Inventory CRM automatically corrects movements, assigns differences to the appropriate expense items, and recalculates the margin at the SKU and category level.

This eliminates manual formulas and errors, and inventory in CRM remains consistent with the facts. For goods with serial numbers, the system maintains a traceability chain, simplifying claims work and audits. Financial registers receive consistent data – reports on channel and seller profitability reflect the real margin after inventory corrections.

Reporting on Shrinkage Rate and Accuracy Rate

Separate dashboards show key metrics: accuracy rate by zone and shift, shrinkage rate in monetary terms and percentages, percentage of incidents by reason, reconciliation time, and rescans. Filters allow comparing periods, warehouses, channels, and responsible parties.

Fast warehouse inventory daily updates these indicators, so they can be tied to team KPIs and process SLAs. For merchandising and procurement, ABC-XYZ slices are available, showing how discrepancies affect the availability of fast-moving SKUs and lost sales. This forms a transparent basis for decisions, and online warehouse accounting transitions from reactive error correction to preventive management.

Improvement Plan Based on Detected Anomalies

Analytics identifies systemic causes: locations with increased shrinkage, SKUs with frequent incidents, picking routes where omissions occur. Based on this, an action plan is formed: bin rotation, changes in picking rules, additional labeling, operator training, and label template updates. Inventory CRM allows assigning responsible parties and deadlines, and subsequent cycles check if deviations have decreased. Thanks to the regular cycle, 10-minute inventory becomes a mechanism for continuous improvement, and inventory in CRM embeds solutions into operational practice. As a result, the business achieves stable accuracy indicators, predictable margin, and faster procurement decisions.

Practical Case with HugeProfit

Initial Conditions and Bottlenecks

A network with three warehouses and 7,000 SKUs faced gaps between actual stock and channel data. There were marketplace penalties, returns, and manual corrections in spreadsheets. Inventory in CRM was partially maintained in different systems, and inventories were conducted quarterly, blocking shipments. The goal was to switch to incremental checks and implement 10-minute inventory without stopping sales. HugeProfit Inventory CRM was chosen as a single platform for scanning, reconciliation, and analytics to ensure online warehouse accounting and transparent KPIs.

Process Setup and Staff Training

The team created a unified SKU directory, added barcodes, and labeled locations. In HugeProfit, virtual warehouses for marketplaces, roles and rights, session templates, and zone checklists were set up. Operators use smartphones with cameras, foremen approve exceptions, and accounting controls cost recalculation by batch. Fast warehouse inventory is conducted daily for priority zones: one shelf – one session, 8-12 minutes with photos and reasons for corrections. For high-risk groups, offline mode with subsequent synchronization was launched, and instructions and videos were embedded directly into the session form. Thus, Inventory CRM became part of the daily routine.

Results After the First Week and Long-Term Effect

After 5 working days, the accuracy rate increased from 94.2% to 98.6%, and monetary shrinkage decreased by 37%. Automatic stock publication eliminated double sales, and price synchronization reduced the number of cancellations and claims. Reports show the top 10 SKUs with repeated incidents, allowing changes in placement and picking routes.

After a month, the average session time stabilized between 9-11 minutes, and 10-minute inventory became the standard for all warehouses. Online warehouse accounting ensures consistent data across all channels, and inventory in CRM has become a source for procurement planning and stock rotation. As a result, the business achieved a predictable margin, faster replenishment, and process control without manual tables.

Conclusions and 10-Minute Checklist

Fast Inventory Checklist in HugeProfit

Prepare the foundation: unified nomenclature, barcodes, labeled shelves. Start a session in HugeProfit Inventory CRM, select a warehouse and zone. Ensure equipment readiness: smartphone or data collection terminal, label printer, offline mode. Perform scanning along the shelf route, use instant validation. Record discrepancies with reasons and photos, and have them approved by the foreman. Complete the session and recalculate cost by batch. Publish stock levels to all channels so that online warehouse accounting reflects the facts. Check the dashboard: accuracy rate, shrinkage, exceptions. This order makes 10-minute inventory repeatable and transparent, and inventory in CRM up-to-date every day.

14-Day Implementation Plan

Days 1-3: Normalize directories, generate barcodes, and set role policies. Configure session templates for ABC and zones.

Days 4-6: Pilot at 1 warehouse. 2 sessions per day for 10 minutes, control rescans. Record reasons for discrepancies in Inventory CRM.

Days 7-10: Scale to all warehouses, connect virtual warehouses for channels. Automatically publish stock levels so that fast warehouse inventory immediately affects showcases.

Days 11-14: Stabilize the process, train the team, and correct routes and labels. Include metrics in KPIs and approve regulations where 10-minute inventory is a standard operation.

Control Points and Success Criteria

Accuracy: accuracy rate of 98% in the sample, monetary shrinkage decreases by at least 20% in the first month. Speed: one session up to 10 minutes, no more than 2% exceptions requiring recheck. Synchronization: stock publication to channels within minutes, inventory in CRM consistent with shelf facts. Audit: full action log, photos, reasons, and the ability to roll back erroneous corrections. Management: regular reports and checklists where Inventory CRM becomes the single source of truth, and online warehouse accounting supports procurement planning and stock rotation. The bottom line is simple – the process is managed, the margin is protected, and 10-minute inventory works as a daily accuracy mechanism.

Choose the best plan and grow your business with us

Free

Confident

Experienced

Pro

Join us on Facebook 😉